Key Benefits

Meal distribution with Cablevey delivering uniform meal moisture to each Extruder

Option of SWING Lines that Integrates a Dryer and a Fryer on the same line

Option of Multiple Flavoring System to generate multiple flavors at any instant

Complete automation of the line with PLC & HMI in air-conditioned Panel

Ribbon blenders with dosing automation with pre-set recipes for multiple products

Sieving at multiple locations to prevent the formation of lumps

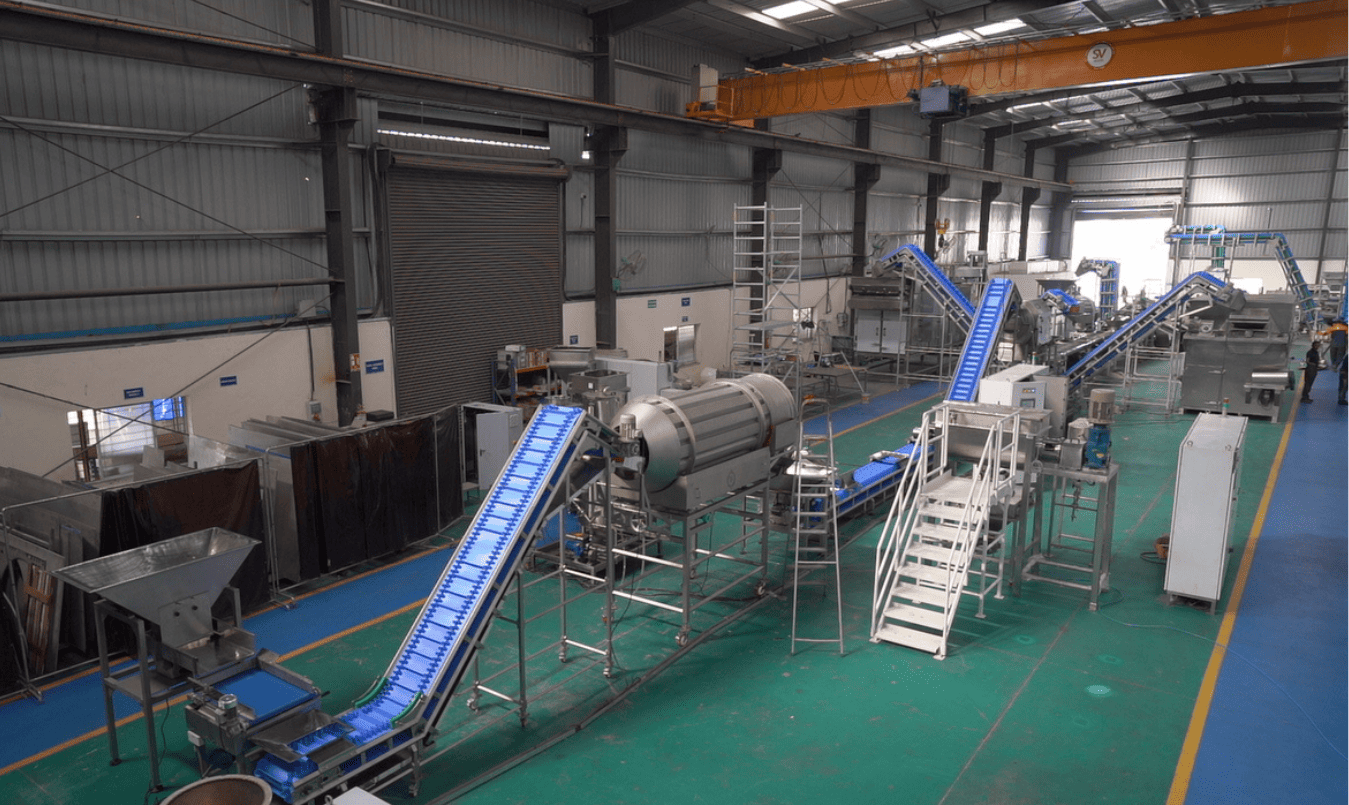

Key Components

MEAL DISTRIBUTION SYSTEM

FRYING & DEOILING SYSTEM

DRYER- 5 LAYER / SINGLE LAYER

RETENTION CONVEYR

SEASONING DRUM

EXTRUDER & CUTTERS

Snacks Components

The extruded snack production line can produce a variety of extruded snacks simply by changing the mixing, heating, and shearing conditions.

- Meal Blending & water addition system

- Meal Distribution system

- Frying & Deoiling System

- Dryer- 5 Layer / Single Layer

- Chaff Tumbler / Nubbin Separator

- Retention Conveyr

- Seasoning Drum

- Extruder & Cutters

- Auto Slurry Preparation & Dispensing system

.webp)

(1).webp)

.webp)