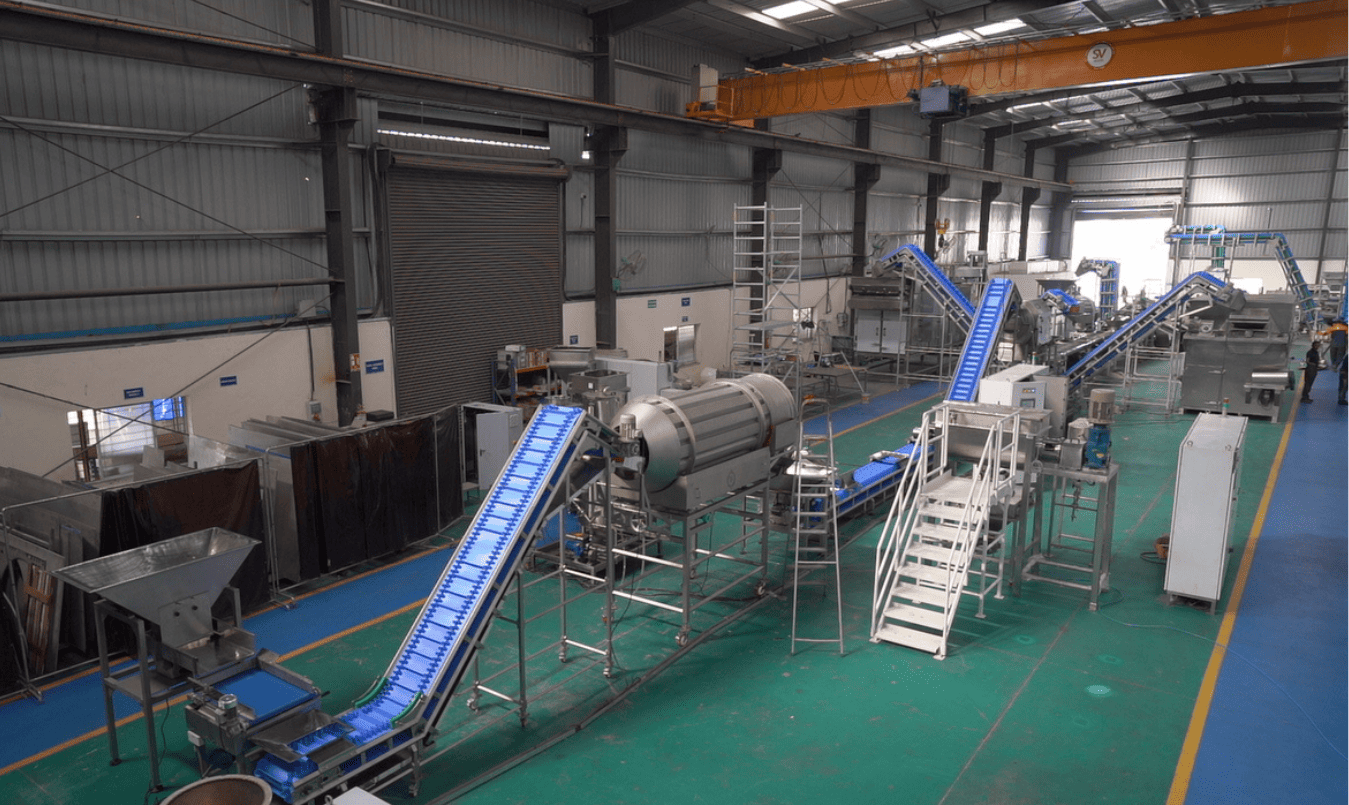

Vacuum Fried Line

Vacuum frying presents an innovative method for transforming fruits and vegetables into delectable, nutritious chips. These chips aren’t just flavorful, but also maintain their valuable nutrients and vitamins.

Their delightful crunchiness makes them a convenient and appetizing option available at any time. Crafting wholesome fruit and vegetable chips is now more effortless than ever before. Thanks to SV Agri production lines, you can commence manufacturing with utmost ease.

.webp)